Railway Trackside Solution

In many countries, people rely heavily on trains or high-speed trains to travel between cities or countries. Owing to greater importance of safety requirements many companies routinely modernize train infrastructure to electrification system so as to deliver efficient, faster and environmentally friendly rail services to passengers. Besides, the network system is also updated from legacy non-IP based to innovative IP-based structure allowing greater integration and operation flexibility.

However, in electrified train system, requirements of switch devices deployed along trackside are different from requirements of switch devices used in old train infrastructure. To name a few, switch devices should be able to avoid impacts or damages caused by electromagnetic disturbances and interference. Moreover, switch devices should be able to withstand vibrations caused by passing trains and able to provide stable and uninterrupted services even under extreme weather conditions. To establish modern and safe rail system, there are several technical challenges that need to be considered.

Challenges

- ● Devices placed along trackside may have high possibilities to be hit by lightning or suffer from ESD and surge.

- ● Non-robust devices become mal-functional because of shocks or vibrations caused by passing high-speed trains.

- ● When a single point of failure occurs in a device, the engineer may not be able to visit the field site immediately to solve the problem.

- ● Outdoor temperature varies greatly from day to night or from season to season. During summertime, the temperature in a metal junction box may reach up to 60°C or higher; however, in winter, temperature may drop to -20°C or lower.

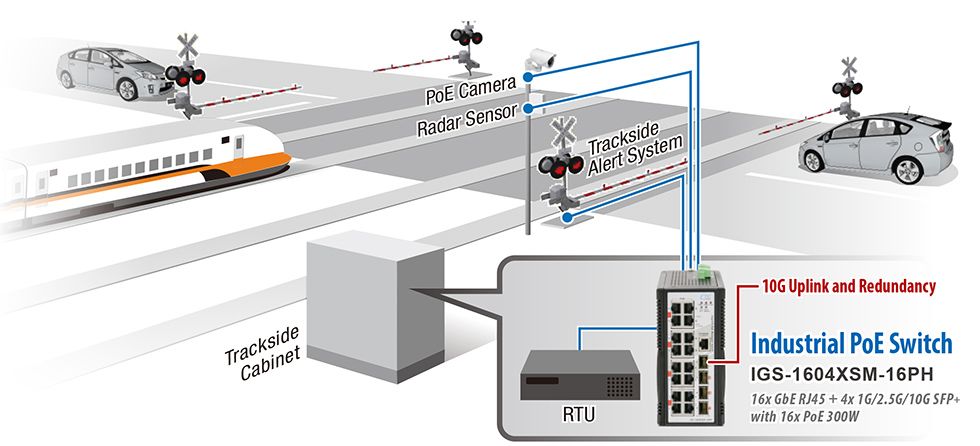

CTC Union's Solution

- ● Provides Industrial grade EMI and EMS certification to offer better protection against unexpected lightning strikes, ESD or surges.

- ● Obtains the EN 50121-4 certification for trackside use.

- ● Supports various and efficient network redundancy (such as u-Ring) mechanisms when a single point of failure occurs. u-Ring can support up to 5 rings (maximum) and can recover from a single point of failure in 10ms.

- ● Supports wide range of operating temperature (-40~70°C) with rugged housing design.

![]()

Application

- Download

-

- Related Products

-

Industrial Managed GbE PoE Switch

IGS-1608SM-16PH

An Industrial 16-port PoE Gigabit Ethernet switch with 8 port 100/1000 SFP slots, each PoE port support IEEE802.3af/at standard of the maximum 30W power...

Details Add to ListIndustrial Managed 10G PoE Switch

IGS-1604XSM-16PH

An Industrial 16-port PoE Gigabit Ethernet switch with 4-port 10 Gigabit SFP+ slot, supporting various types of 10 and 2.5 Gigabit optical small form-factor...

Details Add to ListIndustrial Managed GbE PoE Switch

IGS-804SM-8PH

Industrial grade managed Gigabit PoE switch with 8 Gigabit UTP ports, each port complies with IEEE802.3af/at PoE standard, the total PoE power budget is 240 watts,...

Details Add to ListIndustrial Managed FE PoE Switch

IFS-1608GSM-16PH

An Industrial 16-port PoE Ethernet switch, Layer 2 managed, IFS-1608GSM-16PH with 8 100/1000Mbps SFP slots, each PoE port support IEEE802.3af/at standard...

Details Add to ListIndustrial Managed 10G Switch

IGS-1604XSM

An Industrial 20-port Ethernet switch comes with 16 ports Gigabit copper interface and 4 ports 10 Gigabit SFP+ slots, supporting various types of 10 and 2.5Gigabit...

Details Add to ListIndustrial GbE Switch

IGS-804SM

Industrial-grade managed Gigabit Ethernet switch with 8 Gigabit UTP ports and 4 100/1000 SFP slots for fiber optic connections to meet the requirements...

Details Add to ListIndustrial Managed Fast Ethernet Switch

IFS-1604GSM

The Layer 2 managed industrial Ethernet switch, IFS-1604GSM, has 16 10/100Base-TX UTP ports and is equipped with 4 100/1000Base-X SFP slots for centralized...

Details Add to List